| |

|

| |

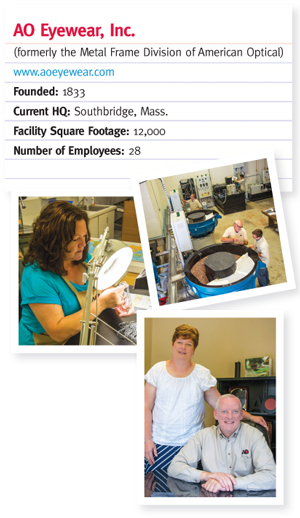

(Clockwise from top left) An AO employee does a final inspection, the frame and component cleaning area and Mary and Alan McKinley, owners. |

| |

|

| |

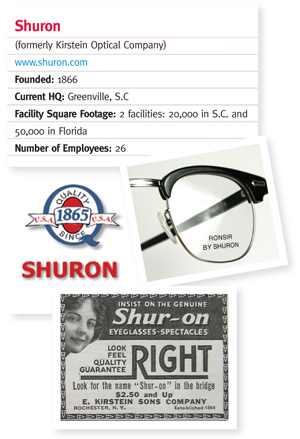

(Clockwise from top left) The current Shuron logo, the classic Ronsir frame from Shuron, a vintage ad. |

| |

|

| |

(Clockwise from top left) Art-Craft factory workers doing presswork

today, workers doing presswork in the first half of the 19th century,

three generations of Eagles. |

| |

|

| |

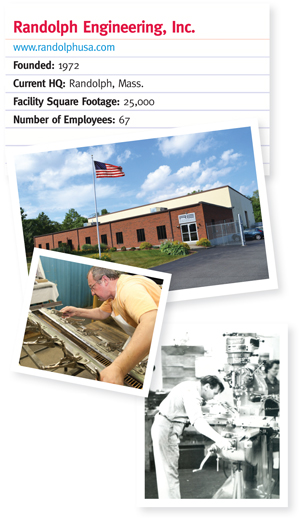

The Randolph Engineering HQ, factory worker making frames today and co-founder, Jan Waszkiewicz in the 1950s. |

| |

|

| |

(Clockwise from top left) The Kala Eyewear factory, Daniel Lau, the “Made in California” Opera frame from Kala. |

| |

|

| |

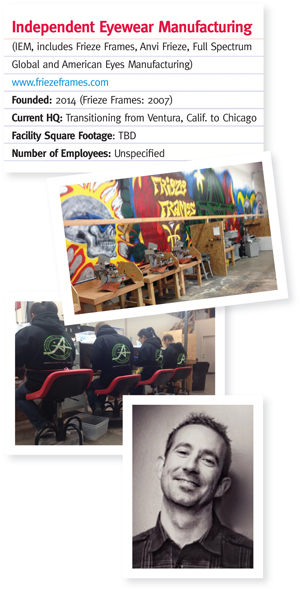

(Top to bottom) Frieze Frames Ventura, Calif. factory and workers. Marc Franchi, right. |